Works

Glass & Colours

The work of coating a surfboard is important constructively and will determine to some extent the character of the surfboard, but no less important is its external appearance. Just as the fact that a person knows how to dress can testify to his manners, so to for a surfboard.

The glassing technique of the 21 Century Industries surfboards has developed over years of experience and specialization in Resin Tint in particular, out of great respect and appreciation for the craft of it. Working in Resin tint requires meticulous attention to the stages of preparing the resin, building the shades & colors from pigment powders and integrating the diverse resin into the glass fabric. A kind of alchemy of colors combined with the craft of composite materials.

Timing is key for achieving appropriate results and no tolerance can be involved when working with Polyester resins. The procedure must be controlled with skills that formed over the years.

Shiny Shoes or Leather Boots

The finishing processes are precise and require endless patience.

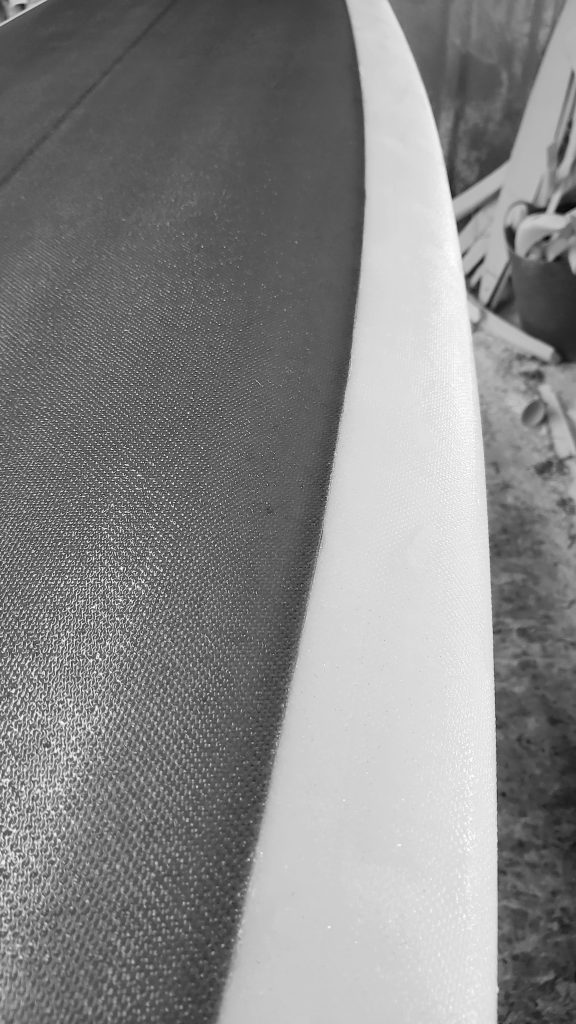

The finish of a board will determine its character to some extent. The last step of the process should be a match for the idea. A glossy polish finish will create a harder surface, a feature that is usually suitable for large boards or those designed to build high momentum.

Polishing creates a uniform molecular order at the surface and contributes to uniform light reflection and the board can reach the levels of a toffee candy. The process is longer thus more expensive.

A silk matte finish will determine a somewhat softer surface and gives more sensitive feedback from the board, the smooth surface of the board will "receive" the surfer in an ergonomic way and the flexibility of the board will be maintained. A matte finish is more suitable for boards that are light in feel, with deep feedback from the board.